Table of Contents

Benefits of Using a 22mm 25mm Fully Automatic Machine

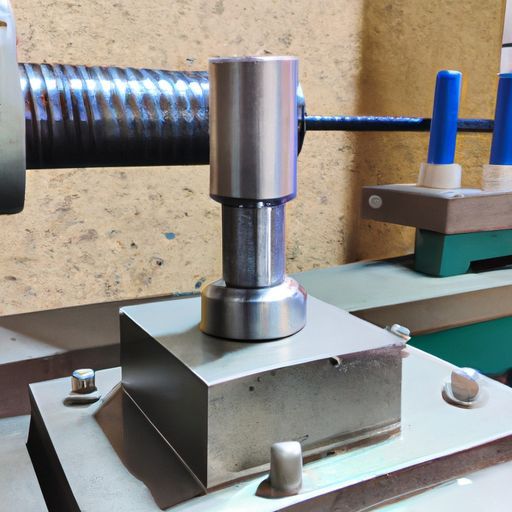

In the manufacturing industry, efficiency and precision are key factors in ensuring the success of a business. One way to achieve this is by utilizing advanced machinery such as the 22mm 25mm fully automatic machine. This state-of-the-art equipment offers a wide range of benefits that can greatly improve the production process and ultimately Lead to higher quality products.

One of the main advantages of using a 22mm 25mm fully automatic machine is its ability to streamline the manufacturing process. With its automated features, this machine can perform tasks quickly and accurately, reducing the need for manual labor and minimizing the risk of errors. This not only saves time but also increases productivity, allowing businesses to meet deadlines and fulfill orders more efficiently.

Furthermore, the 22mm 25mm fully automatic machine is designed to be versatile and adaptable to various production needs. Whether it is used for nut forming, shear connector flux ball riveting, or Aluminum ball installation, this machine can handle a wide range of tasks with precision and consistency. This versatility makes it a valuable asset for businesses that require flexibility in their manufacturing processes.

In addition to its efficiency and versatility, the 22mm 25mm fully automatic machine also offers improved Safety features. With its automated operation, there is less risk of accidents or injuries caused by human error. This not only protects workers but also reduces the likelihood of costly downtime due to workplace incidents.

Another benefit of using a 22mm 25mm fully automatic machine is its cost-effectiveness. While the initial investment may be higher than traditional machinery, the long-term savings in labor costs and increased productivity can result in significant returns on investment. Additionally, the high level of precision and consistency provided by this machine can lead to fewer defects and rework, further reducing costs and improving overall product quality.

Moreover, the 22mm 25mm fully automatic machine is designed to be user-friendly, with intuitive controls and easy maintenance procedures. This makes it accessible to operators of all skill Levels, reducing the need for extensive training and ensuring that the machine can be quickly integrated into existing production processes.

Overall, the benefits of using a 22mm 25mm fully automatic machine are clear. From increased efficiency and productivity to improved safety and cost-effectiveness, this advanced equipment offers a wide range of advantages that can help businesses stay competitive in today’s fast-paced manufacturing industry. By investing in this state-of-the-art machinery, companies can streamline their production processes, enhance product quality, and ultimately achieve greater success in the market.

How to Choose the Right 19B6S Nut Former Equipment

When it comes to choosing the right 19B6S nut former equipment, there are several factors to consider in order to ensure that you are making the best investment for your business. These machines are essential for creating high-quality Nuts and Bolts, and selecting the right equipment can make a significant difference in the efficiency and productivity of your operations.

When it comes to choosing the right 19B6S nut former equipment, there are several factors to consider in order to ensure that you are making the best investment for your business. These machines are essential for creating high-quality Nuts and Bolts, and selecting the right equipment can make a significant difference in the efficiency and productivity of your operations.

One of the first things to consider when choosing a 19B6S nut former equipment is the size and capacity of the machine. These machines come in various sizes, ranging from 10mm to 19mm, and it is important to select a machine that can accommodate the size of nuts and bolts that you will be producing. Additionally, you will want to consider the production capacity of the machine, as this will determine how many nuts and bolts can be produced in a given amount of time.

Another important factor to consider when choosing a 19B6S nut former equipment is the level of automation that the machine offers. Fully automatic machines are ideal for high-volume production, as they can operate continuously without the need for manual intervention. On the other hand, semi-automatic machines may be more suitable for smaller operations that do not require as much production capacity.

In addition to size, capacity, and automation, it is also important to consider the quality and durability of the machine. Look for machines that are made from high-quality materials and are built to last. This will ensure that your investment is protected and that you will be able to rely on your equipment for years to come.

When choosing a 19B6S nut former equipment, it is also important to consider the specific features and capabilities that are important to your operations. For example, some machines may offer additional functions such as shear connector flux ball riveting or aluminum ball installation. These features can help to streamline your production process and improve the quality of your products.

Finally, it is important to consider the reputation and reliability of the manufacturer when choosing a 19B6S nut former equipment. Look for manufacturers that have a proven track record of producing high-quality machines and providing excellent customer service. This will ensure that you are investing in a machine that will meet your needs and that you can rely on for years to come.

In conclusion, choosing the right 19B6S nut former equipment is essential for ensuring the success of your operations. By considering factors such as size, capacity, automation, quality, features, and manufacturer reputation, you can make an informed decision that will benefit your business in the long run. Take the time to research and compare different machines to find the one that best meets your needs and budget. With the right equipment, you can improve the efficiency and productivity of your operations and produce high-quality nuts and bolts that meet the needs of your customers.

The Advantages of Shear Connector Flux Ball Riveting Machine Aluminum Ball Installation Machine for 10mm 13mm 16mm 19mm Applications

Shear connector flux ball riveting machines and aluminum ball installation machines are essential equipment in various industries, especially for applications requiring 10mm, 13mm, 16mm, and 19mm sizes. These machines offer numerous advantages that make them indispensable for businesses looking to streamline their production processes and improve efficiency.

One of the key advantages of shear connector flux ball riveting machines and aluminum ball installation machines is their fully automatic operation. This means that once the machine is set up and running, it can continue to work without the need for constant supervision. This not only saves time and labor costs but also ensures consistent and precise results, leading to higher quality products.

In addition to their automatic operation, these machines are also highly versatile and can be used for a wide range of applications. Whether you need to install aluminum Balls, shear Connectors, or Rivets, these machines can handle it all with ease. This versatility makes them a valuable investment for businesses that work on a variety of projects and need equipment that can adapt to different requirements.

Furthermore, shear connector flux ball riveting machines and aluminum ball installation machines are designed for efficiency. With their high-speed capabilities and precision engineering, these machines can significantly increase production output while maintaining quality standards. This can help businesses meet tight deadlines and fulfill large orders without compromising on the final product.

Another advantage of these machines is their durability and reliability. Built to withstand the rigors of industrial use, shear connector flux ball riveting machines and aluminum ball installation machines are made from high-quality materials that ensure long-lasting performance. This means that businesses can rely on these machines to deliver consistent results day in and day out, reducing downtime and maintenance costs.

Moreover, shear connector flux ball riveting machines and aluminum ball installation machines are easy to operate and maintain. With user-friendly interfaces and intuitive controls, operators can quickly learn how to use these machines effectively, reducing training time and minimizing errors. Additionally, routine maintenance tasks are simple and straightforward, ensuring that the machines remain in top condition for years to come.

In conclusion, shear connector flux ball riveting machines and aluminum ball installation machines offer numerous advantages for businesses working on applications requiring 10mm, 13mm, 16mm, and 19mm sizes. From their fully automatic operation and versatility to their efficiency, durability, and ease of use, these machines are essential tools for improving production processes and achieving high-quality results. By investing in shear connector flux ball riveting machines and aluminum ball installation machines, businesses can enhance their competitiveness, increase productivity, and meet the demands of a fast-paced market.