Table of Contents

Benefits of Using 13Cr Casing Pipe (C95) in Oilfield Operations

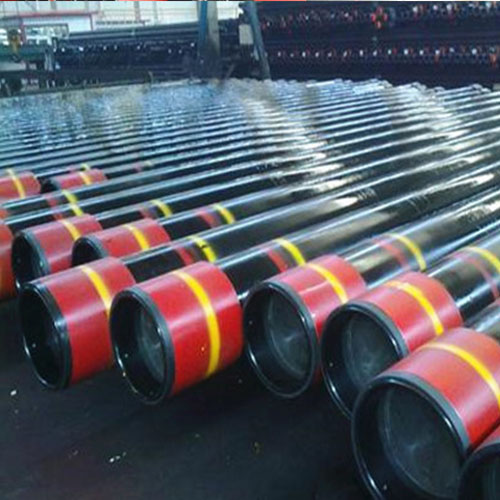

Oilfield operations require durable and reliable equipment to ensure the success and Safety of drilling projects. One essential component of oilfield operations is the casing pipe, which plays a crucial role in maintaining the integrity of the wellbore. In recent years, 13Cr casing pipe (C95) has emerged as a popular choice for oilfield service due to its superior corrosion resistance and mechanical properties.

One of the key benefits of using 13Cr casing pipe (C95) in oilfield operations is its high resistance to corrosion. Corrosion is a major concern in the oil and gas industry, as it can Lead to equipment failure, leaks, and environmental damage. 13Cr casing pipe (C95) is made from a special type of Stainless Steel that contains 13% chromium, which significantly enhances its resistance to corrosion in harsh environments. This makes it an ideal choice for wells that are exposed to corrosive fluids or high Levels of hydrogen sulfide.

In addition to its corrosion resistance, 13Cr casing pipe (C95) also offers excellent mechanical properties that make it well-suited for demanding oilfield applications. The high chromium content in the steel alloy provides superior strength and toughness, allowing the casing pipe to withstand high pressure and temperature conditions. This ensures the integrity of the wellbore and prevents any potential leaks or failures during drilling and production operations.

Furthermore, 13Cr casing pipe (C95) is known for its excellent weldability, which makes it easier to install and maintain in the field. Welding is a common process in oilfield operations, as it is used to connect casing joints and repair any damage to the pipe. The superior weldability of 13Cr casing pipe (C95) ensures that the welds are strong and reliable, reducing the risk of leaks or failures at the joints.

Another advantage of using 13Cr casing pipe (C95) in oilfield service is its cost-effectiveness. While the initial cost of 13Cr casing pipe may be higher than traditional Carbon Steel pipes, the long-term savings from reduced maintenance and replacement costs make it a more economical choice in the long run. The superior corrosion resistance and mechanical properties of 13Cr casing pipe (C95) result in longer service life and fewer repairs, ultimately saving time and money for oilfield operators.

In conclusion, 13Cr casing pipe (C95) offers a range of benefits for oilfield operations, including superior corrosion resistance, excellent mechanical properties, and cost-effectiveness. Its high chromium content provides enhanced protection against corrosion in harsh environments, while its strength and toughness ensure the integrity of the wellbore under high pressure and temperature conditions. The weldability of 13Cr casing pipe (C95) makes it easy to install and maintain in the field, further reducing the risk of leaks or failures. Overall, 13Cr casing pipe (C95) is a reliable and durable choice for oilfield service, helping to ensure the success and safety of drilling projects.

Best Practices for Maintaining and Extending the Lifespan of 13Cr Casing Pipe (C95) in Oilfield Service

13Cr casing pipe, also known as C95, is a popular choice for oilfield service due to its high strength and corrosion resistance properties. However, like any other equipment used in the oil and gas industry, proper maintenance is essential to ensure the longevity and performance of 13Cr casing pipe. In this article, we will discuss some best practices for maintaining and extending the lifespan of 13Cr casing pipe in oilfield service.

One of the most important factors in maintaining 13Cr casing pipe is regular inspection. Inspecting the pipe for any signs of corrosion, wear, or damage is crucial in identifying potential issues before they escalate. This can be done through visual inspections, as well as non-destructive testing methods such as ultrasonic testing or magnetic particle inspection. By catching any problems early on, you can prevent costly repairs or replacements Down the line.

In addition to regular inspections, proper handling and storage of 13Cr casing pipe is also essential. When handling the pipe, it is important to avoid dropping or dragging it, as this can cause damage to the protective coating and compromise the integrity of the pipe. Proper storage is also crucial, as exposure to moisture or harsh weather conditions can lead to corrosion. Storing the pipe in a dry, covered area away from direct sunlight can help prevent damage and extend its lifespan.

Another key aspect of maintaining 13Cr casing pipe is proper cleaning and maintenance. Keeping the pipe clean and free of debris can help prevent corrosion and prolong its lifespan. This can be done by regularly washing the pipe with a mild detergent and water, and inspecting it for any signs of rust or corrosion. If any issues are found, they should be addressed promptly to prevent further damage.

In addition to regular cleaning, applying a protective coating to the 13Cr casing pipe can help enhance its corrosion resistance properties. There are various types of coatings available, such as epoxy or polyurethane coatings, that can provide an extra layer of protection against corrosion. By applying a protective coating to the pipe, you can help extend its lifespan and ensure optimal performance in oilfield service.

Proper installation and handling of 13Cr casing pipe is also crucial in maintaining its integrity and performance. It is important to follow manufacturer guidelines and industry best practices when installing the pipe to ensure it is done correctly. Improper installation can lead to stress on the pipe, which can cause damage and compromise its strength and corrosion resistance properties. By following proper installation procedures, you can help prevent issues and ensure the longevity of the pipe in oilfield service.

In conclusion, maintaining and extending the lifespan of 13Cr casing pipe in oilfield service requires regular inspection, proper handling and storage, cleaning and maintenance, application of protective coatings, and proper installation. By following these best practices, you can help ensure the longevity and performance of 13Cr casing pipe in oilfield service, ultimately saving time and money in the long run.